PRODUCTS

RECRUIT

BUSINESS

Etc Solution

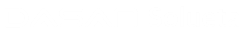

Bezel foam t ape

- Description

-

Developed PU foam type with high tensile strength to secure impact resistance and toughness for TV bezel

- Development direction

-

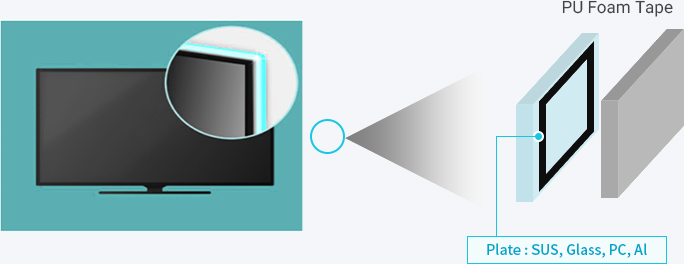

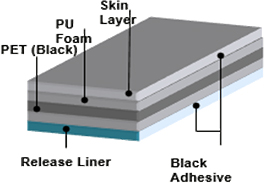

Category Generation 1 Generation 2 Concept Double-sided adhesive Skin Laminate Description

Technology PU Foam + PSA PU Foam + Skin + PSA Advantages High adhesion High adhesion/retention

Excellent reworkability/Reworkable

Excellent processabilityDisadvantages Not reworkable

Non-ReworkHigh unit cost

Process complexityOther Development completed 1. TPU with skin properties, PU application review

2. Giving the adhesive a skin function

3. PE Skin

- Specialized Technology

-

- 01. PSA (Pressure Sensitive Adhesive) characteristics

-

- a. High crosslinking density

- b. Low initial adhesion (Tack) → Reduced compatibility with substrate, high cohesiveness

- c. High cohesion → Excellent heat and chemical resistance of adhesives

- d. Can be attached to high squeezing force

- 02. Technical characteristics

-

- a. Product design technology considering the physical properties of PU foam (CFD, Foam Density)

- b. PU Foam and combination based on high-reliability new PSA Recipe development technology

- c. Process conditions (coating, lamination, etc.) optimization technology

- 03. Maximize performance

-

- a. Maximization of adhesion characteristics: Normal temperature test, low temperature test, high temperature test, storage test, aging test

- b. Maximize retention characteristics: Normal temperature test, low temperature test, high temperature test, high temperature and humidity test

- c. T-Block characteristics maximized: Adhesion Retention T-Block Test, T-Block Limit Test

- d. Understanding and utilizing PU Foam specifications (foam density, CFD, Skin/Foam thickness)

Properties Hard Type PSA Reliability Assessment Soft Type PSA Adhesion OK Room temperature OK OK Low temperature N.G or △ or adhesive transition occurs OK High temperature N.G or △ or adhesive transition occurs OK High temperature and humidity*24hr OK OK High temperature and humidity*48hr N.G or △ or adhesive transition occurs T-Block OK Apply 500g pendulum OK OK Apply 1.5kg weight N.G or △ or adhesive transition occurs

High adhesion tape

- Description

-

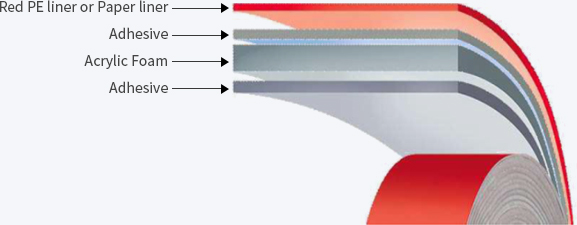

- Acrylic foam tape for mounting vehicle interior and exterior parts

- Excellent impact resistance, tensile strength, durability, and chemical resistance in various conditions provide excellent adhesion

- Able to absorb physical stress from the external environment

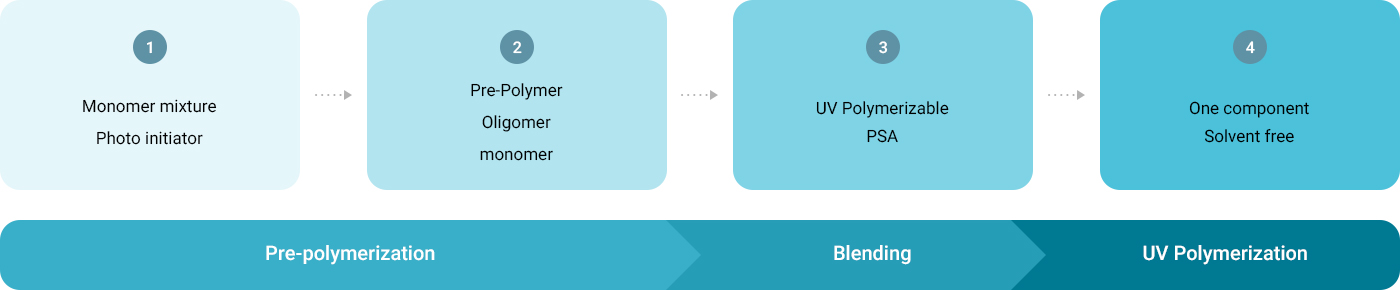

- Manufacture process

-

- Lower energy cost and better quality control possible

- Improved adhesion to various surfaces

- Low VOC emissions

- Fast curing speed

- High solvent resistance, heat resistance, chemical resistance, UV stability

- Specification

-

Item Unit SHA (G) 64 SHA (G) 80 Test Method Total Thickness ㎛ 640㎛ ± 10% 800㎛ ± 10% Digital Upright Gauge Color Gray Liner description White paper or Red PE liner Density Kg/㎥ 0.78 0.77 SUS Peel Strength N/25㎜ 38 over 43 over 180˚ Peel, ASTM D3330 Holding Power 10,000min Pass ASTM D3654 Dynamic Shear Strength N/25㎟ 630 over 600 over ASTM D3654

- SUS Peel Strength Properties : N/25mm, 300mm/min, 25microns PET film backing, after 72hr

- Holding Power Properties : 130℃ /1,000g/10,000min/ 25mm*25mm, after 5min

-

Dynamic Shear Strength Properties : 25 mm*25 mm size, load cell:5KN

Peel speed :10 mm/min, Peel angle: 180 degrees after 72hr

- Automobile

-